Special modifications

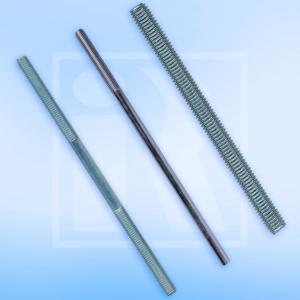

Reduction or nominal thread: For some uses, a part with the same diameter on the thread as the starting wire needs to be manufactured. This is done by reducing the threaded area before this operation, thus achieving, for example, that a wire with a nominal diameter of 10 mm results in an M10 thread component.

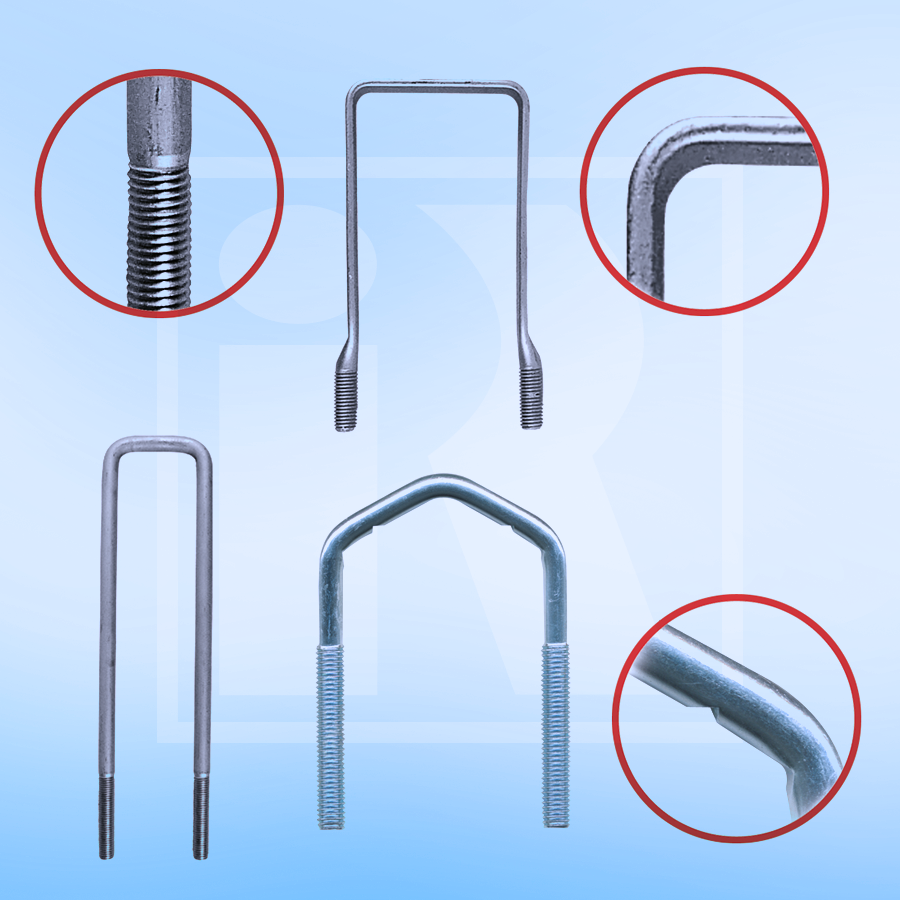

With mark: On many occasions, a U-bolt needs a series of marks to help it adapt better to the profile where it will be placed. Depending on their depth, these marks can be done automatically in the manufacturing process or in a subsequent operation.

Stamped: When the U-bolt has to fit better to the tubing to be clamped, the wire can be shaped for this purpose. This can be achieved with cold bending, or if a greater bend is required, the bar can be heated before forming.