The objective of Auxiliary Integraled Solutions is to work with a customer that needs metal attachments according to the following steps:

- Establish the product.

- Make the necessary calculations to confirm the product is suitable.

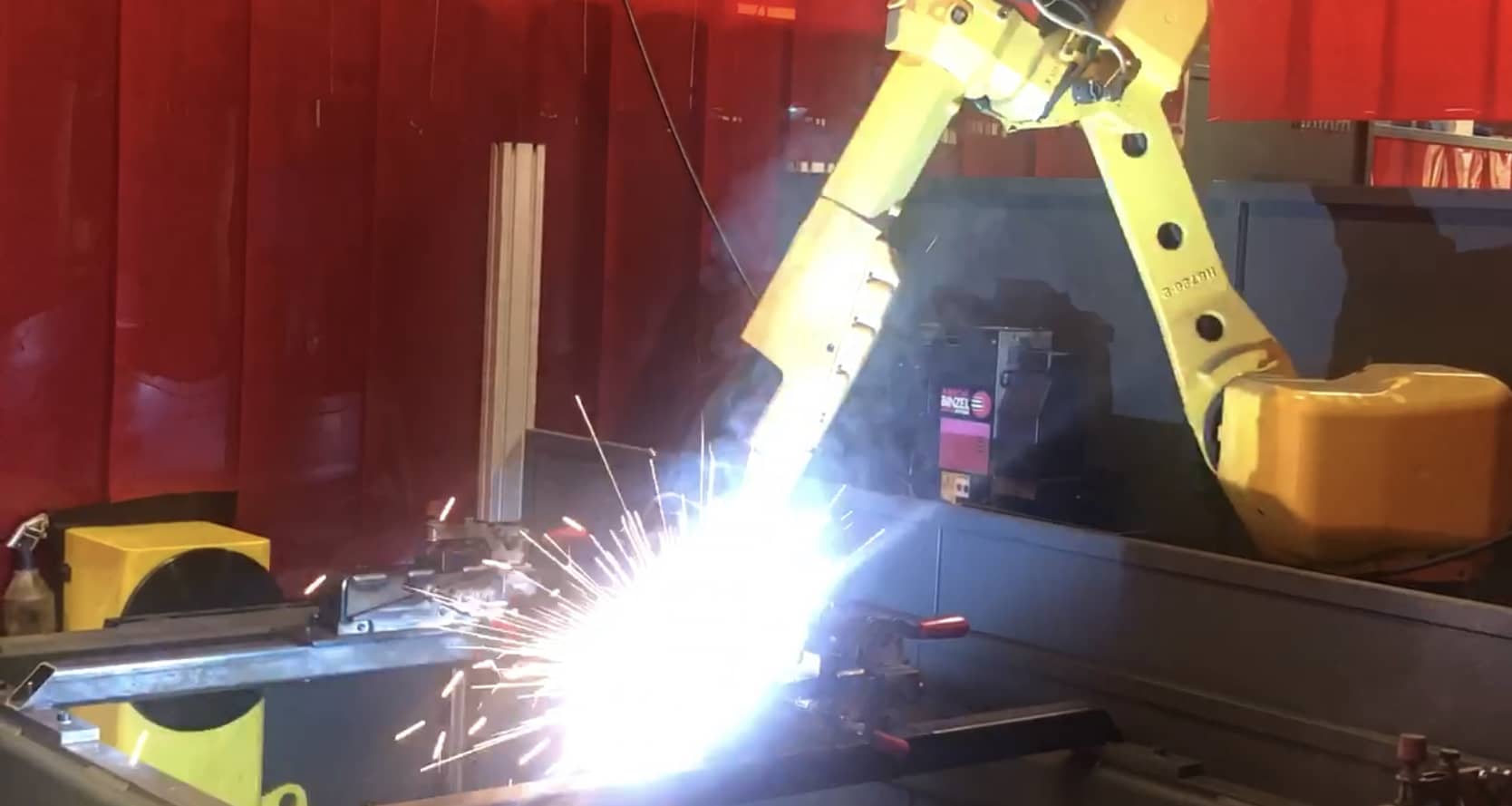

- Assess the production system based on the quantity and time required.

- Manufacture the production die if required.

- Series production and surface treatment.

- Packing and delivery to the customer.